Certified ELIN Motoren Repairs Now Available in Western Australia

We are proud to announce that National Electric Motor Services Pty Ltd has been appointed the exclusive and only authorised repair facility for ELIN Motoren (a Voith Company) in

We are proud to announce that National Electric Motor Services Pty Ltd has been appointed the exclusive and only authorised repair facility for ELIN Motoren (a Voith Company) in

HV failure modes; Reminder! Insulation Deterioration: Over time, the insulation materials used in motor windings may degrade due to environmental factors, such as high temperatures,

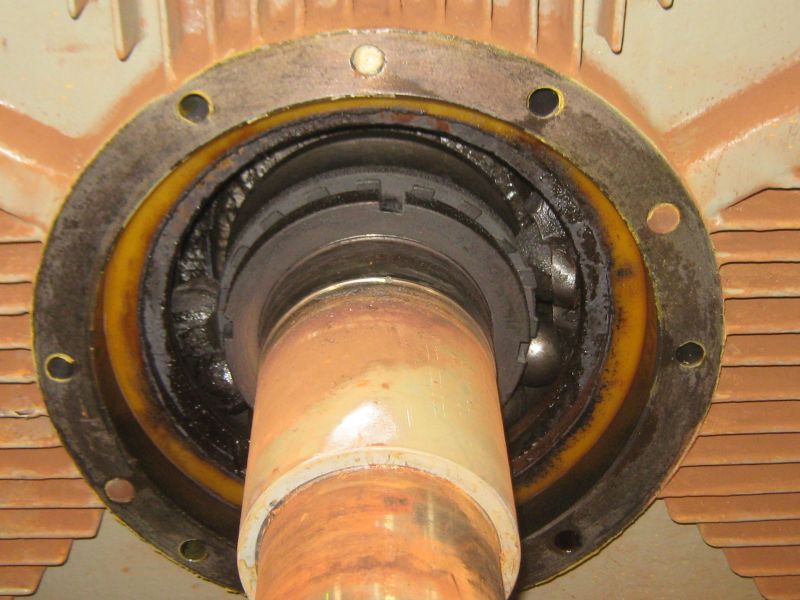

What is that noise… There are many reasons why bearings can fail in electric motors. Here are some common causes: Insufficient lubrication: Bearings require proper

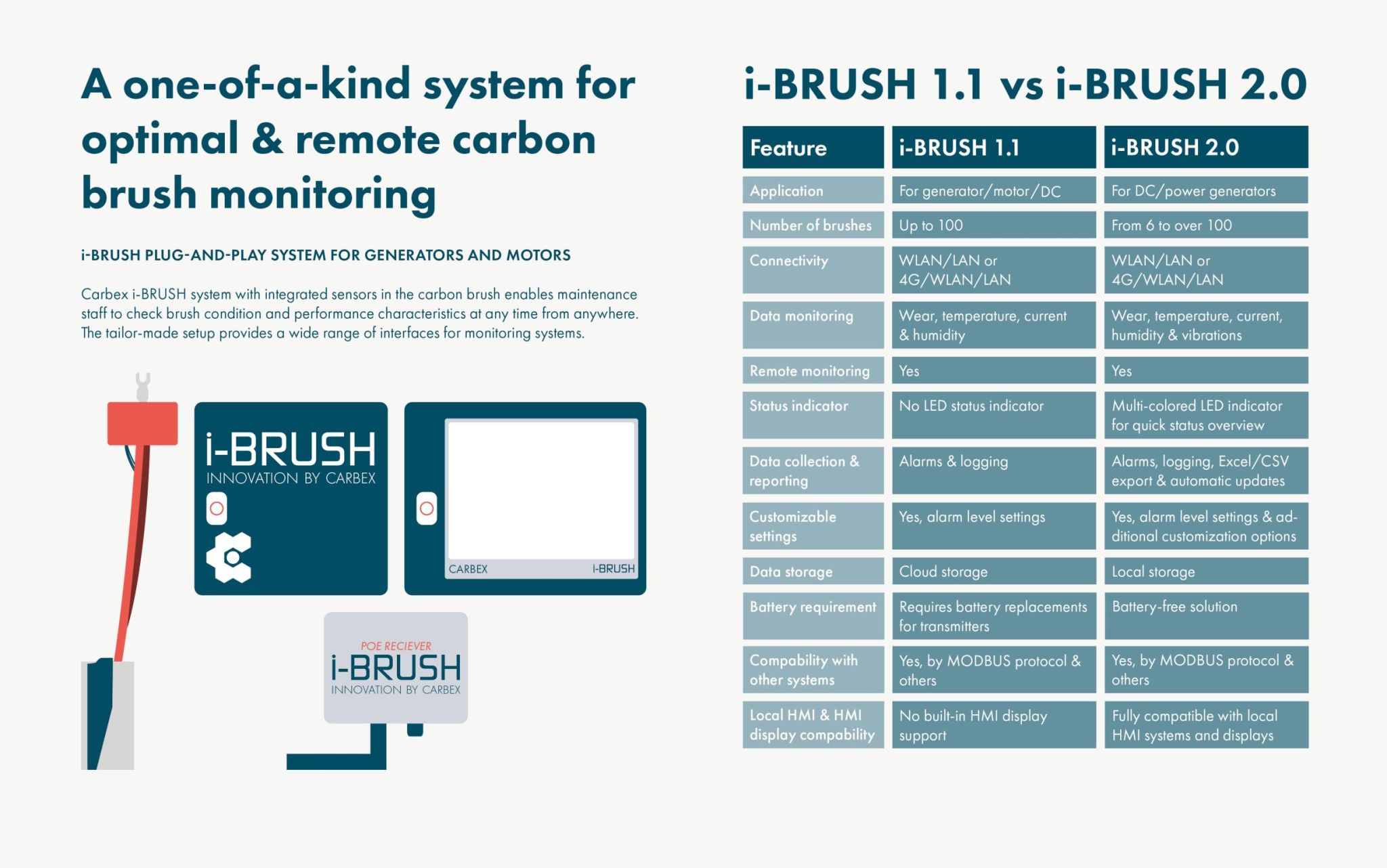

Can you communicate carbon brushes? We can! With i-BRUSH from Carbex AB, you get live data on brush wear, temperature, and performance—directly from your motor

Windings Failures In the world of electric motors, random wound configurations have long been favoured for their versatility and performance. However, even in these common

Some more possible failure modes to be considered: Ingress of Moisture: Exposure to moisture or water ingress can compromise the insulation integrity of motor windings.

Thanks again to everyone who visited with us at the MESCWA2024 ! Great conversations about reliability, maintenance and Carbex AB iBRUSHmonitoring Thanks to MESA Mine

Improve efficiency and extend the life of your electric motor with an Electric Motor Rewind. Electric motors are critical components in a vast range of

What a successful recent visit to Australia by the team from Carbex, where they presented their ground-breaking i-BRUSH system. This wireless carbon brush monitoring technology

Below are some common causes of bearings failing in electric motors. Insufficient lubrication: Bearings require proper lubrication to reduce friction and prevent wear. If there

Electric motors are made using specific bearing designs, high-quality bearings and high-quality lubricants. All reputable OEMs will provide you with the bearing information, recommended lubrication

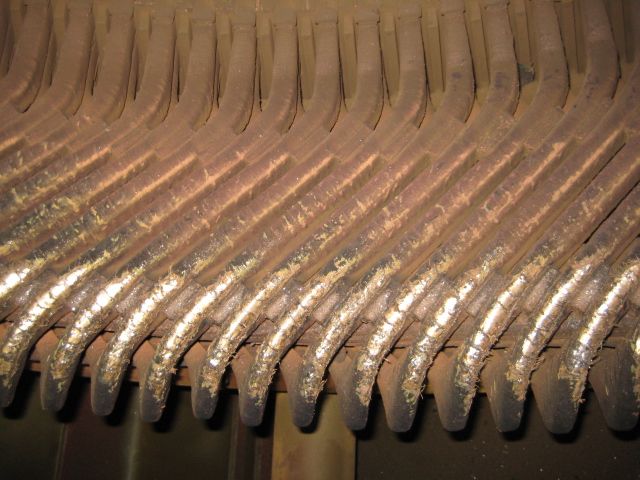

By understanding these potential causes, engineers and maintenance professionals can take proactive steps to mitigate slip ring failures. 1. Contamination: The slip rings can accumulate

Are you involved in the mining industry? If so, you know how critical it is to keep your machinery running smoothly and efficiently. And at

These are the most common failures modes: *Insulation Deterioration*: Over time, the insulation materials used in motor windings may degrade due to environmental factors, such

IP ratings, or Ingress Protection ratings, are a standardised system used to classify and rate the degree of protection provided by electrical enclosures, including electric

Completing regular (PD) partial discharge testing is crucial for electric motors to detect insulation problems early, prevent catastrophic failures and extend motor lifespan. Off-line PD