Why do motors fail…

Some of the following are common causes:

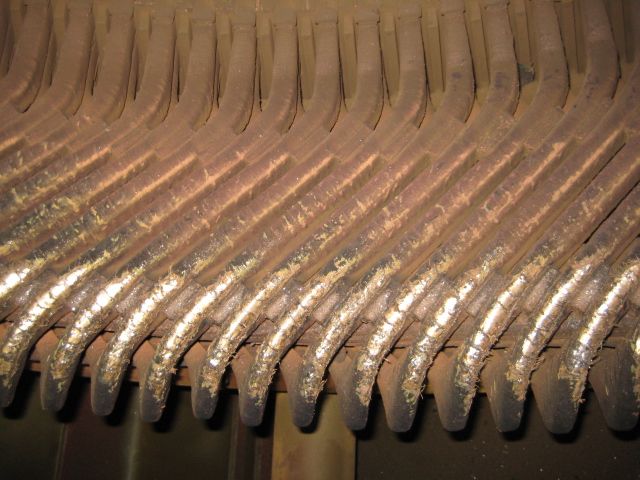

Insulation Breakdown: One common culprit behind windings failures is insulation breakdown. Over time, environmental factors such as temperature fluctuations, moisture ingress, and mechanical stresses can compromise the insulation integrity, leading to short circuits and eventual failure.

Thermal Stress: Random wound motors often operate in demanding environments, subjecting their windings to significant thermal stress. Rapid temperature changes, overload conditions, or inadequate cooling can accelerate insulation aging and contribute to thermal breakdown.

Voltage Spikes: Electrical transients, such as voltage spikes and surges, pose another threat to winding integrity. These transient over voltages can exceed the insulation’s breakdown voltage, causing arcing and insulation degradation over time.

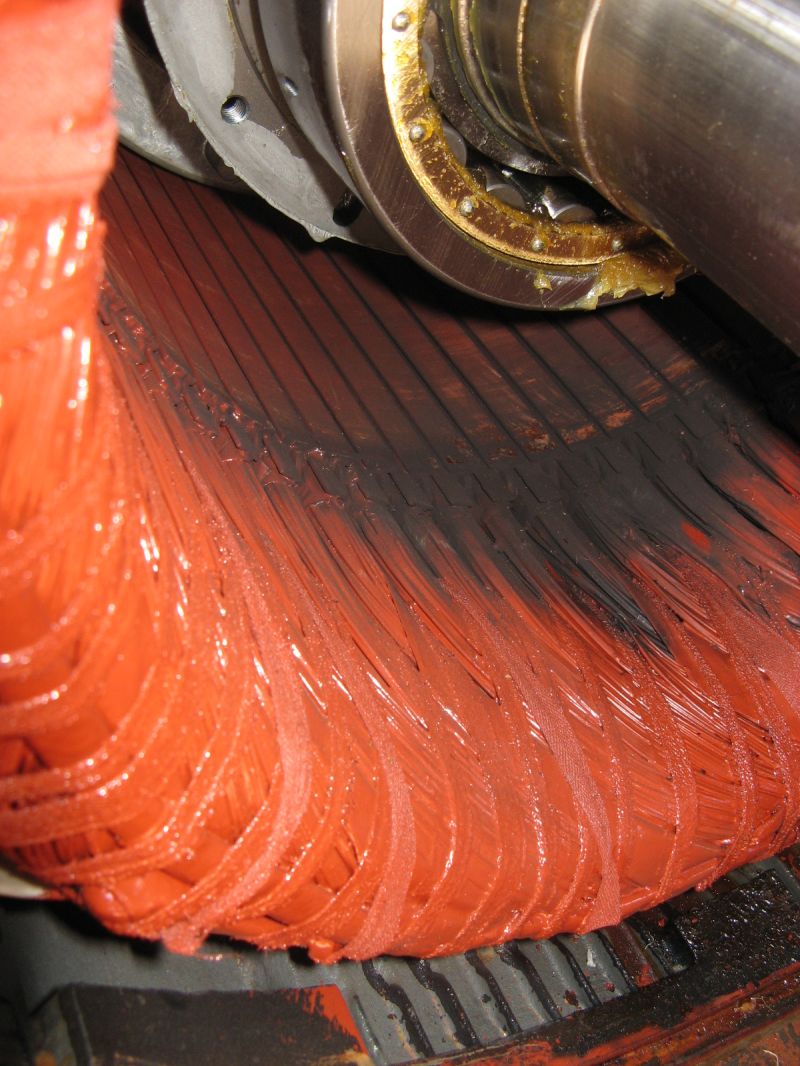

Vibration and Mechanical Stress: The inherent vibration and mechanical strain experienced by motors in operation can also take a toll on winding health. Excessive vibration can lead to insulation abrasion, while mechanical strain from misalignment or shaft deflection can cause winding deformation and eventual failure.

Regular inspections, thermal monitoring, and vibration analysis can help identify early signs of deterioration, allowing for timely intervention and preventive measures. Additionally, selecting high-quality insulation materials suited to the motor’s operating environment can enhance performance.