What is that noise…

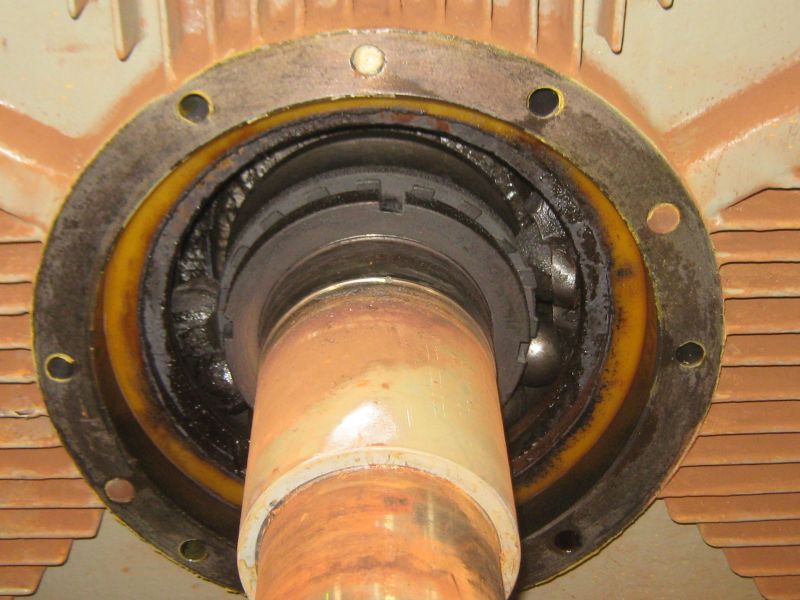

There are many reasons why bearings can fail in electric motors.

Here are some common causes:

Insufficient lubrication: Bearings require proper lubrication to reduce friction and prevent wear. If there is inadequate lubrication the bearings can experience excessive friction and heat, leading to premature failure.

Contamination: Foreign particles such as dust, dirt, or debris can enter the bearing. Contaminants can accelerate wear and cause abrasion, leading to failure.

Overloading: Subjecting bearings to excessive loads beyond their design capacity can cause them to wear out quickly. Overloading can result from factors like excessive torque, over-speed during operation, or sudden shock loads.

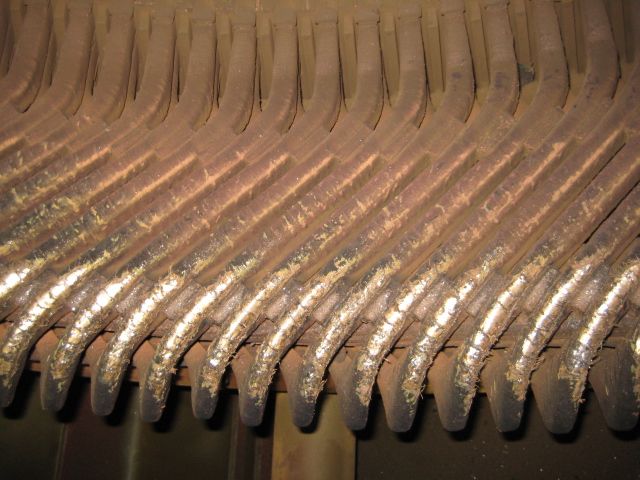

Electrical currents: Electric motors can generate stray currents due to factors like improper grounding or variable frequency drives. These currents can flow through the bearings, causing arcing and pitting on the bearing surfaces, leading to failure.

Vibration and misalignment: Excessive vibration or misalignment will put additional stress on the bearings. Continuous exposure to such conditions can lead to failure.

Aging and wear: Over time, bearings naturally wear out due to usage and fatigue. The rolling elements and the bearing raceways can develop signs of wear, leading to increased friction, noise, and eventual failure.

It is important to note that multiple factors can contribute to bearing failure, and often, a combination of these factors may be involved. Regular maintenance, proper lubrication, and monitoring can help prevent failures.