Windings Failures

In the world of electric motors, random wound configurations have long been favoured for their versatility and performance. However, even in these common designs, windings failures can emerge as a perplexing challenge, impacting reliability and productivity. Let’s look into these failures to shed light on their causes and solutions.

Insulation Breakdown: One common culprit behind windings failures is insulation breakdown. Over time, environmental factors such as temperature fluctuations, moisture ingress, and mechanical stresses can compromise the insulation integrity, leading to short circuits and eventual failure.

Thermal Stress: Random wound motors often operate in demanding environments, subjecting their windings to significant thermal stress. Rapid temperature changes, overload conditions, or inadequate cooling can accelerate insulation aging and contribute to thermal breakdown.

Voltage Spikes: Electrical transients, such as voltage spikes and surges, pose another threat to winding integrity. These transient over voltages can exceed the insulation’s breakdown voltage, causing arcing and insulation degradation over time.

Vibration and Mechanical Stress: The inherent vibration and mechanical strain experienced by motors in operation can also take a toll on winding health. Excessive vibration can lead to insulation abrasion, while mechanical strain from misalignment or shaft deflection can cause winding deformation and eventual failure.

Regular inspections, thermal monitoring, and vibration analysis can help identify early signs of deterioration, allowing for timely intervention and preventive measures.

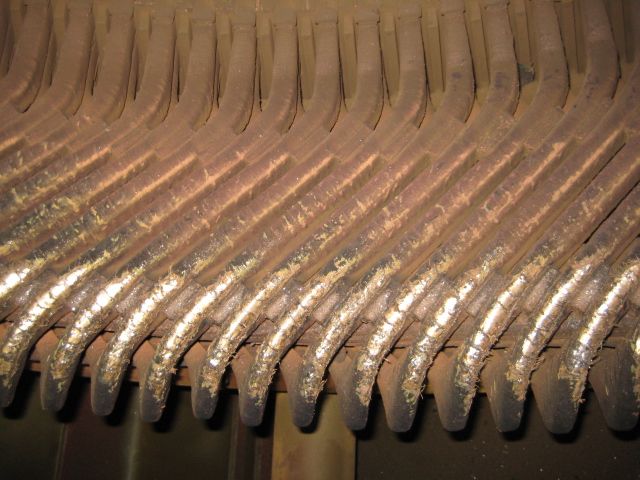

Here you can see a close up of heat stress on windings, this occurs when windings within electric motors operate at temperatures beyond recommended and designed limits, leading to accelerated wear and breakdowns.

What causes heat stress in electric motors?

Overloading: Running motors beyond their rated capacity increases current which results in heat production.

Poor Ventilation: Inadequate cooling due to blocked ventilation paths or improper installation can cause heat build up.

Ambient Temperature: Operating motors in excessively hot environments without adequate cooling can exacerbate heat stress.

Frequent Starts and Stops: Rapid temperature fluctuations during frequent start-stop cycles stress windings.

Improper Maintenance: Lack of regular inspections, cleaning, and lubrication can contribute to heat-related issues.

So how can you protect electric motors…

Proper Sizing and Selection: Ensure motors are appropriately sized for their intended workload.

Regular Maintenance: Implement a proactive maintenance schedule to monitor motor performance.

Improved Ventilation: Enhance airflow around motors through proper installation and ventilation design.

Thermal Monitoring: Use temperature monitoring devices to detect overheating early and take corrective actions.